Background

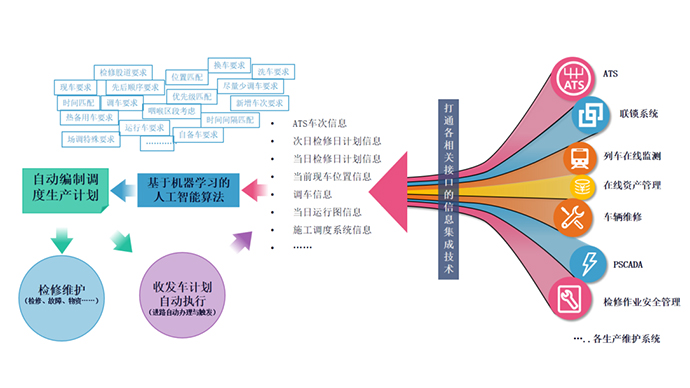

Currently, most metro depots in China rely on outdated production dispatching methods, with low levels of informatization and automation, inefficient planning, poor business coordination, and weak safety control.

Driven by relevant policy documents such as the “Guidelines for Requirements and Implementation of Metro Depot Integrated Automation Management System in Urban Rail Transit”, the product facilitates the intelligent and automated upgrade of depots. It complies with the automation management requirements outlined in GB/T 51268-2017 Regulation for Metro Depot Engineering of Urban Rail Transit, and aligns with the spirit issued in the “Smart Urban Rail Development Outline” by the China Association of Metros.