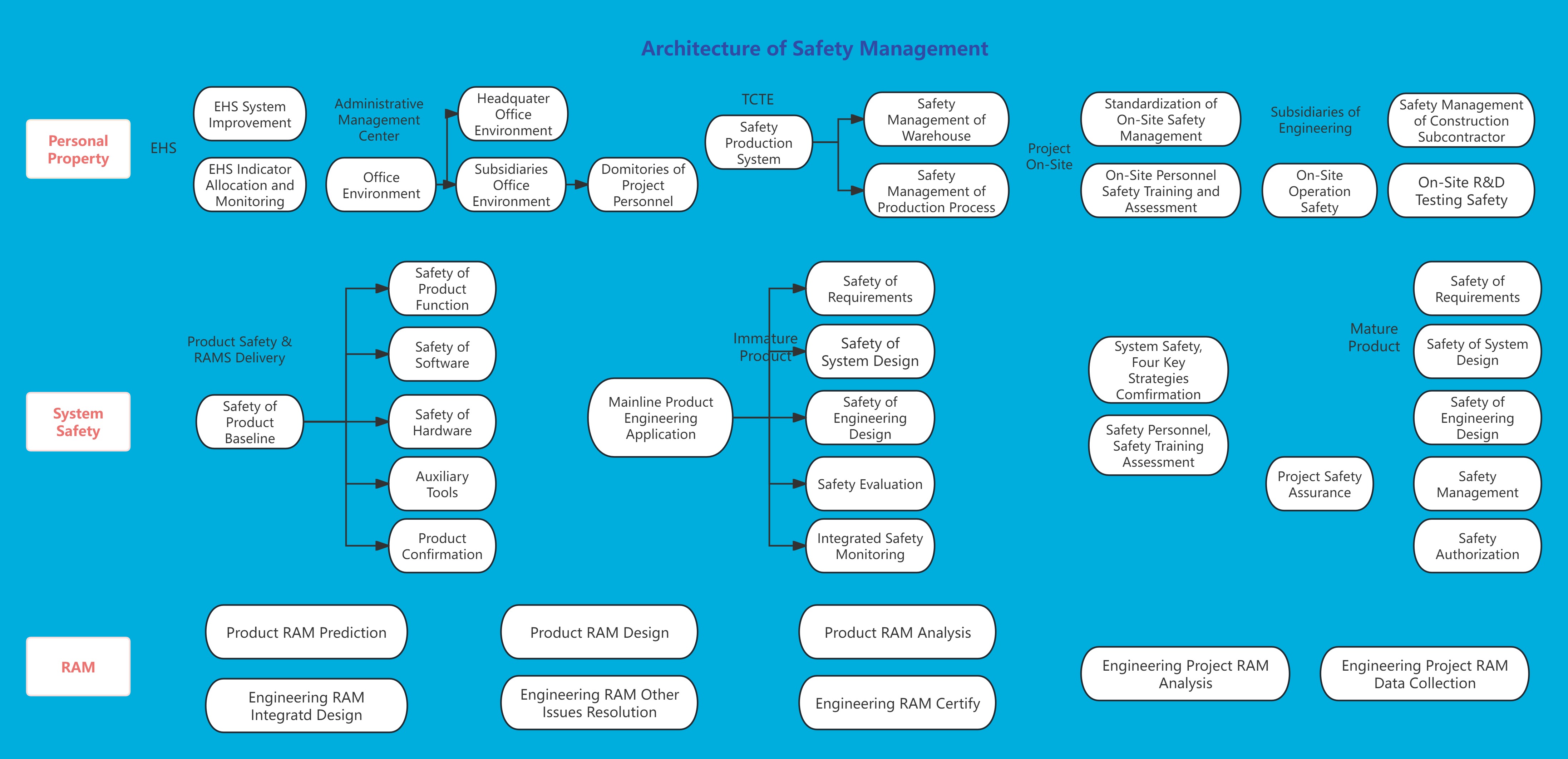

RAMS

All Our products comply with international standards

Meet Standard EN50126/50128/50129 IEE1474、IEC62290/62267/62443、TS50701 etc.

TCT has the intelligent manufacturing system such as SMT intelligent manufacturing platform, multi-functional assembly and test platform, high-speed product life test platform, AGV automatic transfer system, intensive intelligent warehousing, intelligent vertical container, robot arm integration and collaboration system, integrates the above systems with the six informatization management platforms such as product life cycle management (PLM), enterprise resource planning (ERP), manufacturing execution system (MES), quality management system (QMS), intelligent warehousing management system (IWMS) and supplier management system (SRM), forms a flexible digital intelligent factory that integrates automation assembly and test, intelligent logistics and informatization operation management into a whole, and provides personalized multi-dimensional customized service for rail transit industry.

In order to meet the safety-critical requirements for high safety, reliability and quality, fully consider the operation environment of rail transit vehicles, ensure the normal operation of electronic equipment in severe environment conditions and achieve the company’s objectives of high energy efficiency and low energy consumption based on the product performance, users’ demand and future planning of company, TCT products have reached following standards:

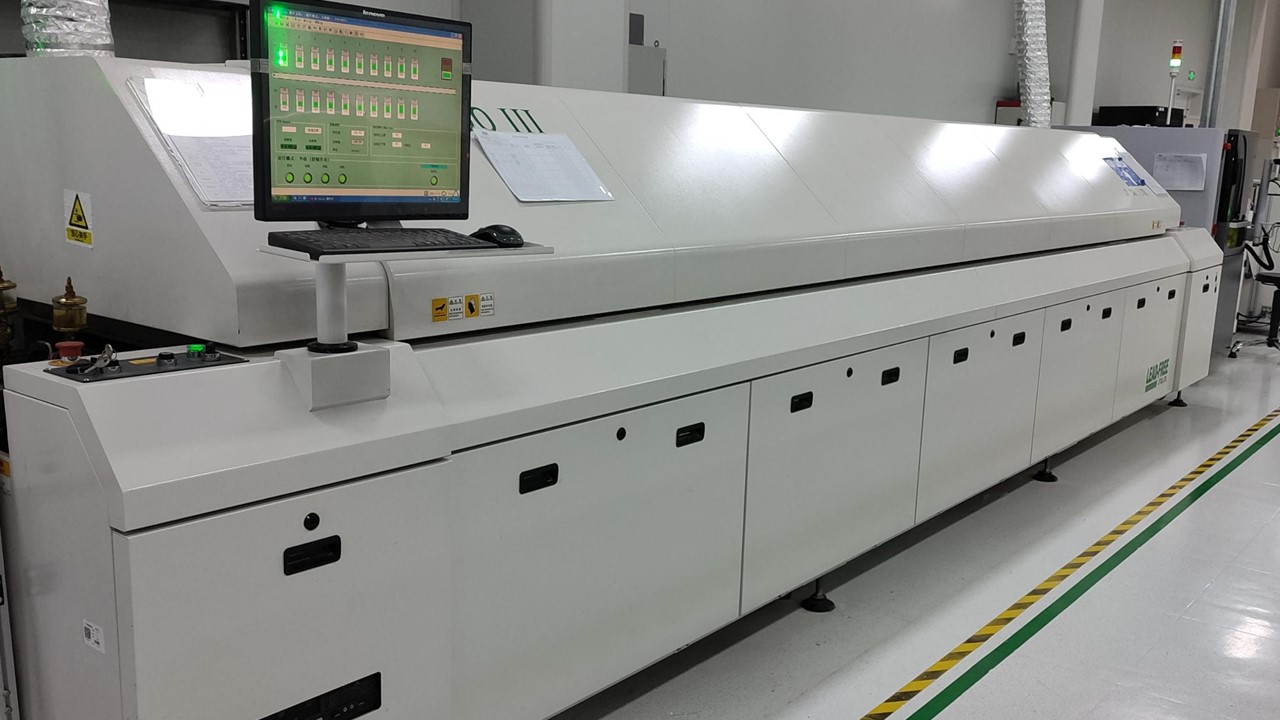

SMT production line is equipped with domestic and foreign manufacturing equipment, which can meet the technical requirement for placing the components (British system: higher than 03015) and square chips (size: less than 32mm*32mm) and irregular elements in line with the rapid development trend of electronic product assembly industry;

Three-proofing coating equipment: all the PCBA plate assembly are coated with three-proofing protective layer and tested before transferring to next process, which ensures the normal operation even in severe environment;

Operate according to the standard test procedures of safety-critical products, ensure that products meet the technical requirements of safety-critical products according to 28 inspection mechanisms such as SPI, AOI (3D), X-Ray (3D) test, three-proofing coating test, strain test, vibration test, high/low temperature test, quick temperature change test, PCBA single board test, full function test and aging test, and meet the research, development and design requirements of products and the customers’ high standard requirements.

Realize digital management of intelligent manufacturing through six informatization management platforms, trace the products in whole life cycle and quickly respond to the customers’ demand.

Workshop shall meet the environmental requirements (temperature: 23℃±5℃; humidity: 55-60%) of equipment manufacturing, and the facilities in workshop shall meet the anti-static requirements.

Create the high temperature aging test environment to meet requirements of accelerated life test and ensure the product reliability;

Implement management according to ISO9001, ISO14001, ISO45001 and ISO/TS22163.