In December 2018, TCT won the bidding of cloud platform project of Hohhot Urban Rail Line 1 and 2 and became the cloud platform integrator and data mining system supplier. From January to April 2019, TCT held 3 design liaison meetings and successfully completed system design, engineering design and interface scheme. From May to August, test platform was built in Helin County to complete tests and verifications such as functions, performance, interconnectivity, fault and disaster recovery.

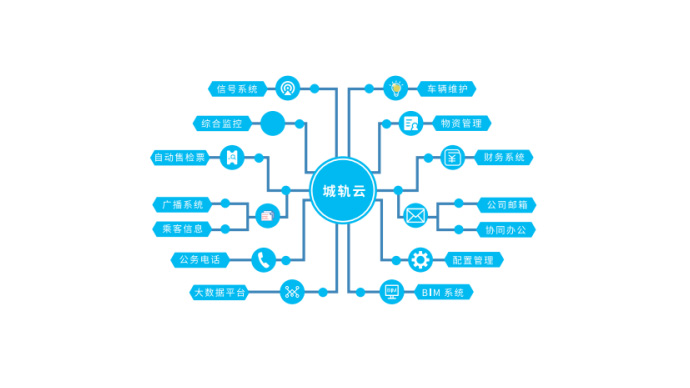

The cloud platform of Hohhot urban rail carried out unified deployment of center/station-level resources for service system cloudification according to the “13531” overall application function structure of urban rail transit informatization proposed by the Association. Phase I cloud platform met the functional requirements for normal operation and maintenance of Hohhot urban rail transit Line 1 and 2, and reserved the access capacity for later planning and construction of Line 3, 4 and 5.

The characteristics of cloud platform such as multiple tenants and expansion can ensure cooperation of multiple applications of different lines on the same cloud platform, so as to support line network operation vigorously.

In this phase, the cloud platform of Hohhot urban rail includes 2 lines which will carry 6 safety production networks, 16 internal management networks and 4 external service networks.

Urban rail cloud platform can realize unified logical management of distributed production center, disaster recovery center, stations and train depot/parking lot, form a cloud resource pool and provide unified operation and maintenance management capability of multiple stations. Unified management platform has the distributed management capability and can deploy cross-resource pool and data center through flexible resource dispatching strategy.

Hohhot big data platform follows the principle of “data drive and innovation through data management and decisions” and gathers various professional system data such as signals and automatic fare collection. Operation information release and management system, production data analysis system and intelligent operation and maintenance management system are established based on real-time monitoring and intelligent analysis. Besides, it integrates service data effectively, plans and utilizes data quickly and accurately and provides basis for management decision and operation.